The Top 5 Service Issues Found During Routine HVAC Maintenance

Most HVAC problems don’t appear overnight. They develop slowly through normal wear, dirt buildup, humidity exposure, and electrical stress. That’s why routine maintenance is such a powerful tool, it catches small problems before they turn into major breakdowns.

At Williams Air Solutions, we perform hundreds of tune-ups each year throughout Pinellas County, and the same few issues show up again and again. Below are the five most common service problems we uncover during routine HVAC maintenance, and why addressing them early saves homeowners money, stress, and discomfort.

1. Restricted Airflow From Dirty Filters and Blowers

Airflow restrictions are the most common issue we find during tune-ups.

Typical causes include:

- Overloaded or neglected air filters

- Dust-coated blower wheels

- Blocked return vents

- Debris buildup in supply vents

- Collapsed or poorly insulated duct runs

Restricted airflow forces systems to run longer and harder, driving up energy use and causing uneven cooling. Over time, this strain leads to frozen coils, burned-out blower motors, and compressor damage.

Fix during maintenance:

Cleaning blower components, replacing filters, and restoring proper airflow immediately improves efficiency and comfort.

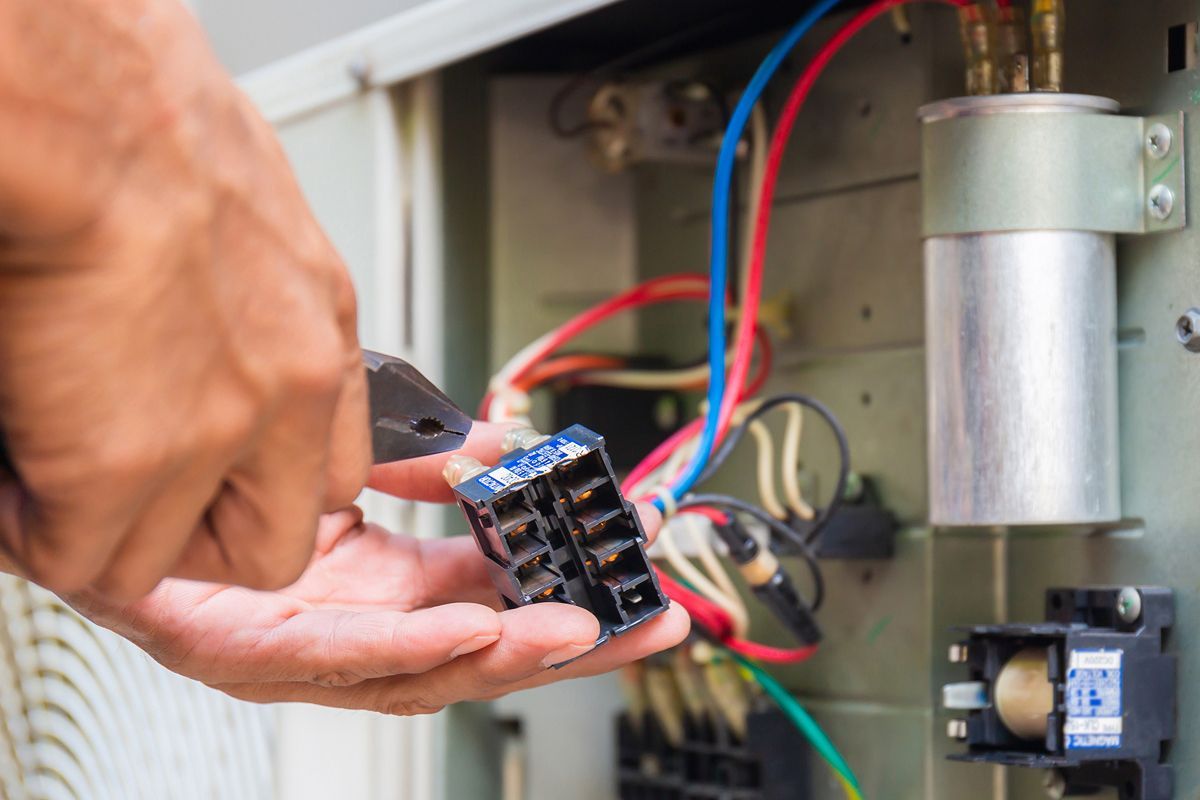

2. Electrical Component Wear (Capacitors and Contactors)

Florida’s heat and humidity accelerate the wear of HVAC electrical parts. Capacitors and contactors are among the most failure-prone components we test during service visits.

Common findings:

- Weak capacitors struggling to start motors

- Burned contact points causing erratic cycling

- Loose wiring connections

- Heat-damaged insulation

These electrical issues are the top cause of sudden AC failures — especially during peak summer demand.

Fix during maintenance:

Testing components early allows replacement of weak parts before breakdown occurs.

3. Dirty Condenser and Evaporator Coils

Coils are responsible for heat exchange — the actual “cooling” process of your HVAC system. Dirt buildup on coils significantly reduces cooling efficiency and moisture removal.

Coil contamination comes from:

- Coastal salt air corrosion

- Dust accumulation

- Pollen and grass debris

- Mold growth from poor drainage

Symptoms of dirty coils include:

- Longer cooling cycles

- Increased humidity

- Rising energy bills

- Lukewarm airflow from vents

Fix during maintenance:

Professional coil cleaning restores cooling performance and reduces unnecessary compressor stress.

4. Clogged or Partially Blocked Drain Lines

High humidity ensures steady condensate production in Florida homes, which makes drain line clogs extremely common.

Clogs are caused by:

- Algae growth

- Mold buildup

- Dust accumulation

- Insects and debris

When not cleared, they lead to:

- Water leaks

- Overflowing drain pans

- Ceiling or wall water damage

- System shutdown via safety float switches

Fix during maintenance:

Drain lines are flushed, cleaned, and treated to prevent backups, stopping water damage before it starts.

5. Improper Refrigerant Levels and Pressure Imbalances

Low refrigerant or improper pressure often develops slowly and goes unnoticed until cooling performance declines significantly.

Problems include:

- Undetected refrigerant leaks

- Poor dehumidification

- Inconsistent cooling

- Long system runtime

Running an AC with improper charge increases energy use and can permanently damage the compressor.

Fix during maintenance:

Technicians perform pressure testing to verify refrigerant operation meets manufacturer specs, catching early leaks before major damage occurs.

Why These Problems Are Rarely Discovered Without Maintenance

Most of these issues develop silently. Homeowners usually notice symptoms only after comfort declines or breakdown occurs, often during the hottest days of summer.

Routine maintenance:

- Identifies hidden issues

- Prevents emergency failures

- Reduces energy waste

- Protects major components

- Improves cooling performance

Preventing a Major Failure in Palm Harbor

During a routine Palm Harbor tune-up, our technician discovered a failing capacitor and heavy coil buildup. Neither issue had yet caused cooling problems. Two weeks later, during a major heatwave, neighboring homes were experiencing system failures — while this customer’s system continued running smoothly.

Preventive maintenance turned a potential breakdown into a simple preventive fix.

Routine Maintenance Prevents Major Repairs

Every major HVAC failure begins as a minor, avoidable problem. Regular professional tune-ups catch those problems before they cost you comfort or thousands in repair bills.

At Williams Air Solutions, our maintenance visits address the most common service issues — keeping your HVAC system running reliably year after year.

Call Williams Air Solutions at (727) 353-0090 today to schedule your commercial HVAC maintenance consultation and prevent the most common system failures.